One thing Celia and I most enjoy about boat life is exploring in our dinghy. When we bought the boat, it came with an older but very nice aluminum AB 9.5 ft. dinghy. It has a nice V-hull, is lightweight for its size, and has high quality construction with hypalon tubes. Although we thought we would downsize when we stopped living in a marina, as we have no davits and would want to stow it on the foredeck for any open water crossings, the fact is we could not bring ourselves to part with it when the day came. Having a high speed dinghy capable of taking a few waves means more snorkeling, mangrove exploring, and ease of getting to shoreside facilities.

With the decision to keep the dinghy came the need to keep the 9.9hp four stroke engine we had. It weighs 85 lbs. Unfortunately, we had no way of getting such a large engine on and off the dinghy for stowage on the rail. Additionally, we had purchased the Garmin package deal on a chartplotter/radar combo a few years ago and had never installed the radar. Truth be told, I might have skipped the radar for our current plans as they stand now if I had it to do again and used that money elsewhere. My only real use for it so far has been on night passages to determine the distance to fishing boats and ships, etc. (which is a good thing). But I digress…

This project involved a lot of planning due to limited space; and in the end, I still screwed up one of the simplest measurements because I estimated (guessed) instead of actually measuring. I wanted to keep with all the other hardware on the boat and stick with stainless steel for this project. Again in hindsight, I may have gone with polished aluminum if I did it again due to weight issues…a 2 1/2 inch diameter 8 ft. stainless tube weighs a lot! All of that said, the finished product came out awesome.

Two 1″ SS struts were added for stability. Hardware was sourced from Garhauer Marine. The two upper attachments basically clamp on the big tube and the lowers are adjustable swivel mounts for the 1″ tube so that the angle and attachment point is adjustable.

These rail standoffs were also necessary to reinforce the stern rail and add stability for the post.

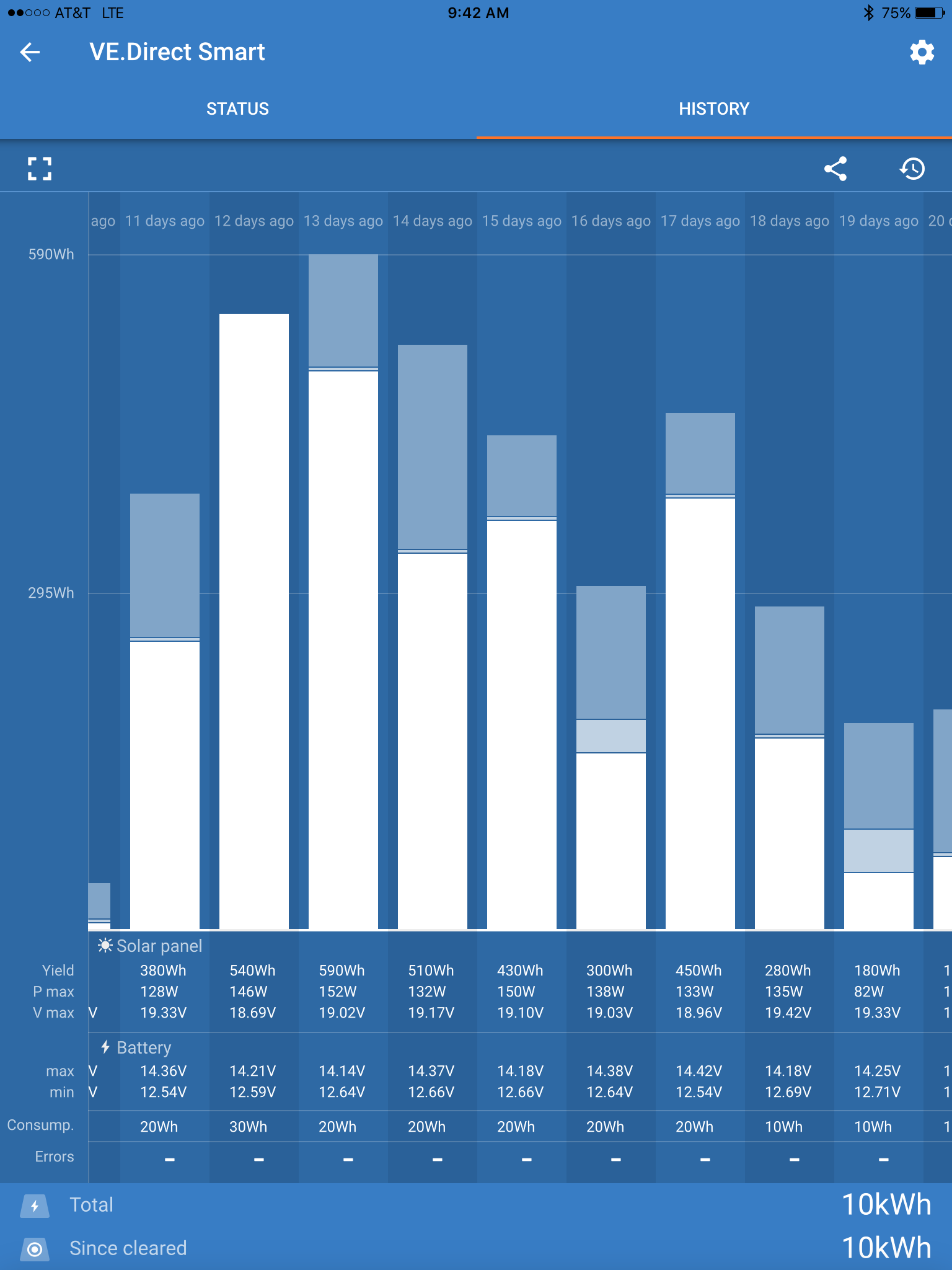

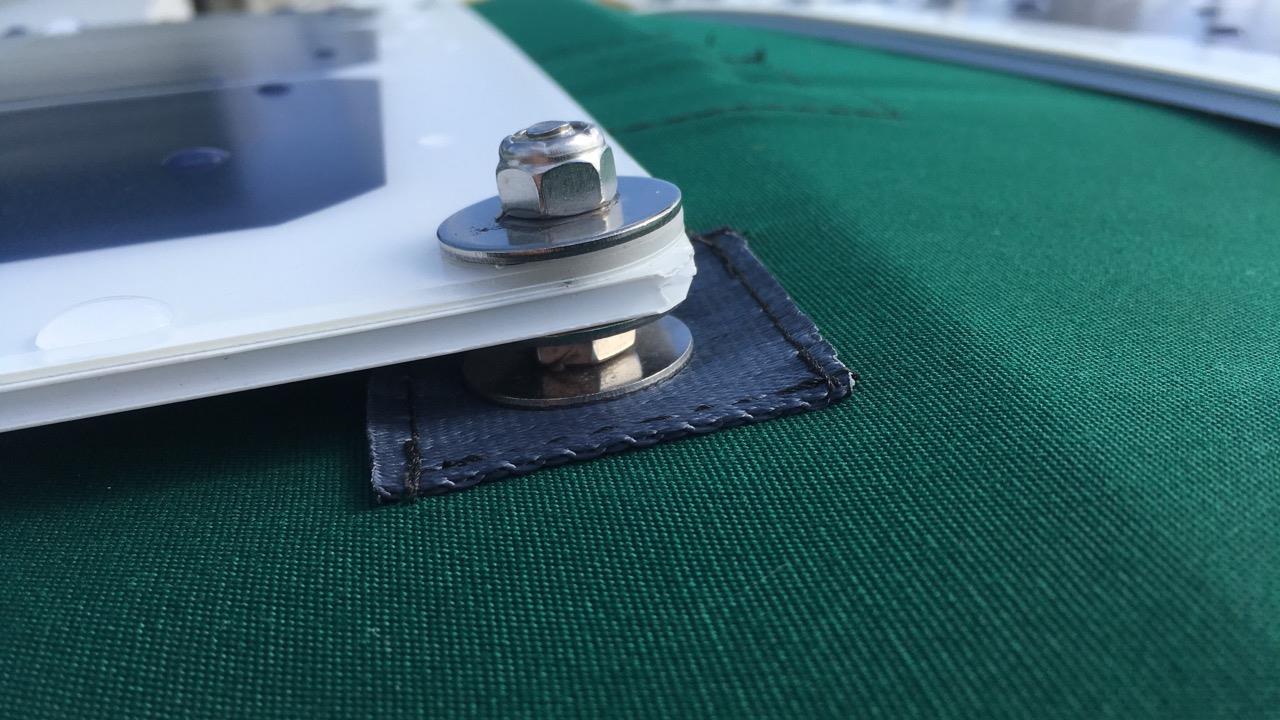

There was no room to spare anywhere so we hunted down hardware that worked for us. The base could probably have used 4 screws instead of 2, but there was not much room to play with under the cap rail. Each 1/4″ screw got its own little backing plate but I wish it could have been one larger one. All the other supports make it a pretty sturdy rig all in all. We drilled holes for the radar wiring to run through the post and ended up running the wiring for the solar panels through the post as well.

Adustable pivoting mount closeup.

We wanted this thing to be bulletproof so we had the outboard engine hoist arm custom fabricated too and had the mounts for that welded directly on the post. Of all the difficult measurements and spacing, this is where I screwed up. I had neither the motor or the block and tackle and engine strap when I chose how high the arm needed to be. I made it too low! I was either going to need a tiny block and tackle system or to reconfigure the arm. This was going to be a costly mistake! I ended up having my welder reconfigure the arm. It caused me to invent a new saying: “Measure twice, PAY once!”. I will update this post with a picture of the new arm as time allows. Any questions about this or other projects, please feel free to contact us!